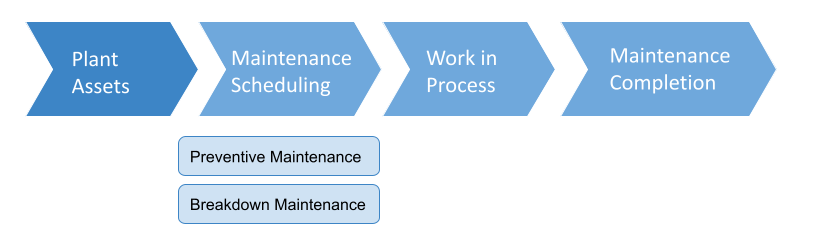

Plant maintenance is the service and repair of assets and equipment. During normal operation, assets may accumulate wear-and-tear that needs to be addressed. Deviations outside of normal operation of cause the majority of damage to equipment and assets. Plant maintenance includes scheduled and unscheduled maintenance. Plant maintenance may be scheduled according to age of equipment or usage of equipment. Unscheduled plant maintenance can occur after equipment failure or operation excursions.

Preventive Maintenance

- Maintenance activity performed to maintain the technical objects in efficient condition. To ensure that the equipment doesn’t malfunction which leads to putting people at risk, affects the production or customer service.

Breakdown Maintenance

- Activities are performed to restore the ideal condition of technical objects. Maintenance is performed on malfunctioned and non operational equipment. The maintenance can be planned or unplanned. The malfunction is corrected by work center responsible for the maintenance of the technical object. After the malfunction is corrected, the order is confirmed by the technician performing task, the maintenance planner and the supervisor.

Maintenance Process

Maintenance Plan

Maintenance Work Order